Welcome to Our Product Gallery

A-1 Automation is committed to quality craftsmanship, innovation , and Customer satisfaction. Below are a few photos and videos featuring a diverse range of feeder bowls and other products which we have worked with our customers to successfully implement into their manufacturing processes

Hoppers and Conveyers

All hoppers and conveyors are meticulously crafted to meet the unique demands of your parts—size, capacity, and functionality. Vibratory hoppers excel when loading height is not a concern; they typically reside on the same table as the bowl, boasting a greater height for efficient loading. Equipped with a paddle switch or down sensor, these hoppers accurately monitor bowl levels, ensuring seamless refilling when necessary.

Constructed from durable stainless steel or carbon steel, our hoppers stand the test of time while maintaining a professional appearance. They can be either hand-polished, electro-polished, painted, or powder-coated. Elevator hoppers, designed for ground-level access, offer effortless loading of parts and elevate them directly into the feeder bowl. Meanwhile, our conveyor systems efficiently transport parts horizontally, streamlining movement from one station to the next. Our hoppers and conveyor systems are tailored to your operational needs.

Custom Tables and Frames

At A1 Automation, we take pride in creating custom tables and frames tailored specifically to meet your unique needs and requirements. Choose from a selection of durable stainless steel, powder-coated mild steel, or lightweight aluminum, each option proudly featuring high-performance tops that are built to last. Our expert design team constructs sturdy frames for automation equipment, offering versatile options such as adjustable steel feet, rubber feet, or convenient castors for added mobility. Your perfect solution is just a request away, and we are ready to collaborate with you. Let us build the ideal table or frame that works just as hard as you do, ensuring a seamless fit for your operations.

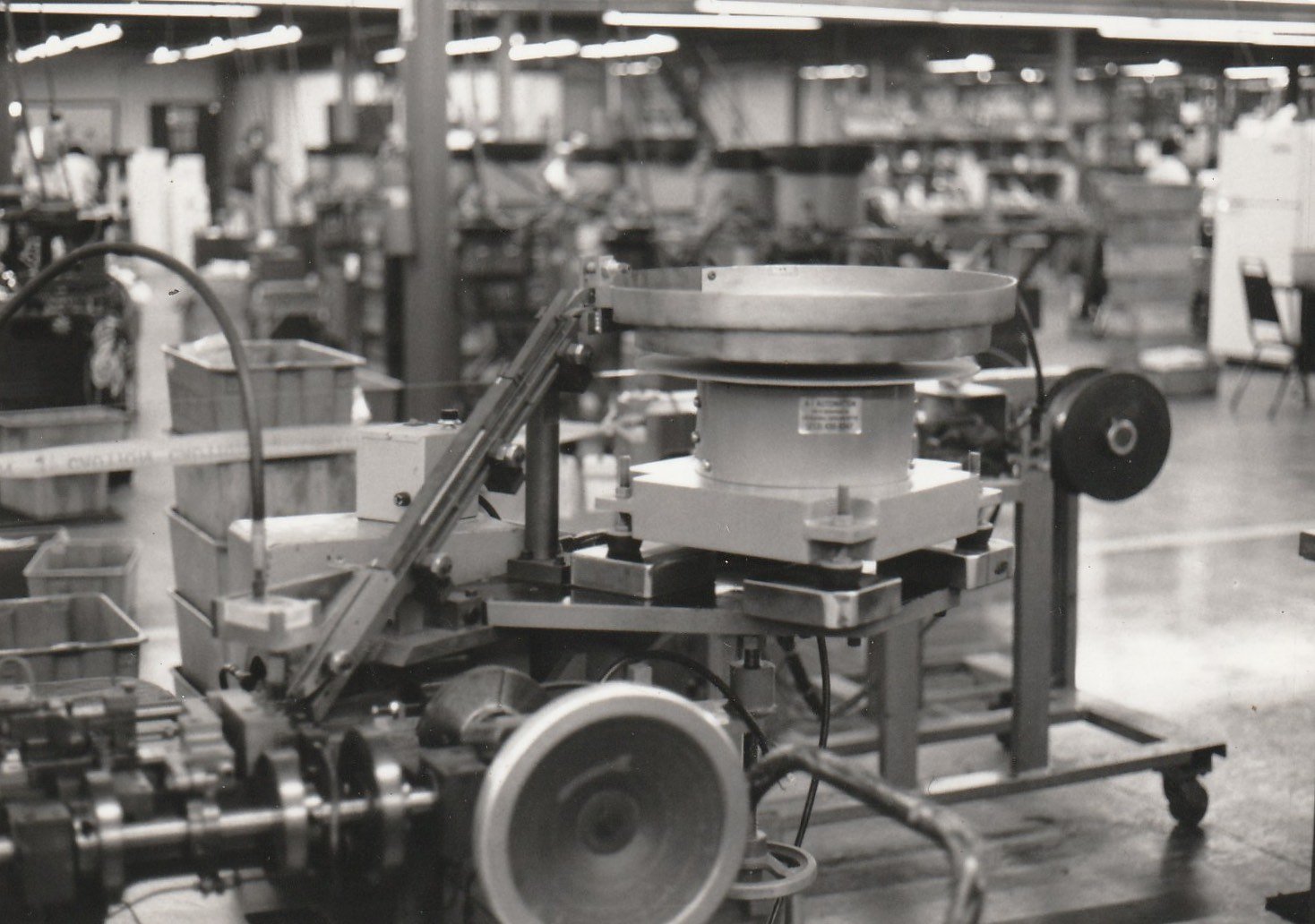

Feeder bowls

Our vibratory feeders are in a league of their own. Crafted from robust 11 gauge 304 and 316 stainless steel, Our feeders offer unparalleled durability. When wear and tear threatens your operation, we’ve got you covered. Our Standard Bowls feature our quick adjustment tooling made from harden A2 or D2 tool steel. They are also available with Teflon or polyurethane coatings, ensuring maximum protection.

Teflon coatings safeguard polished and glass components from marring, while polyurethane coatings effectively dampen noise from heavy metal parts and shield delicate items. For a striking chrome appearance, we can electro-polish our bowls to perfection. Every other bowl is either glass bead blasted or beautifully hand-polished, offering a blend of aesthetics and functionality.

Not to be overlooked, our drive units are available in 120 VAC and 240 VAC configuration. They come standard painted in safety blue but can be painted or powder-coated to match your facility’s color scheme seamlessly. Our standard drives are square base but can be ordered with a round base.

Choose from single-track, multi-track, or adjustable bowls to accommodate a variety of feeding requirements. With A1 Automation, quality is never compromised. Experience the difference, where performance meets excellence.

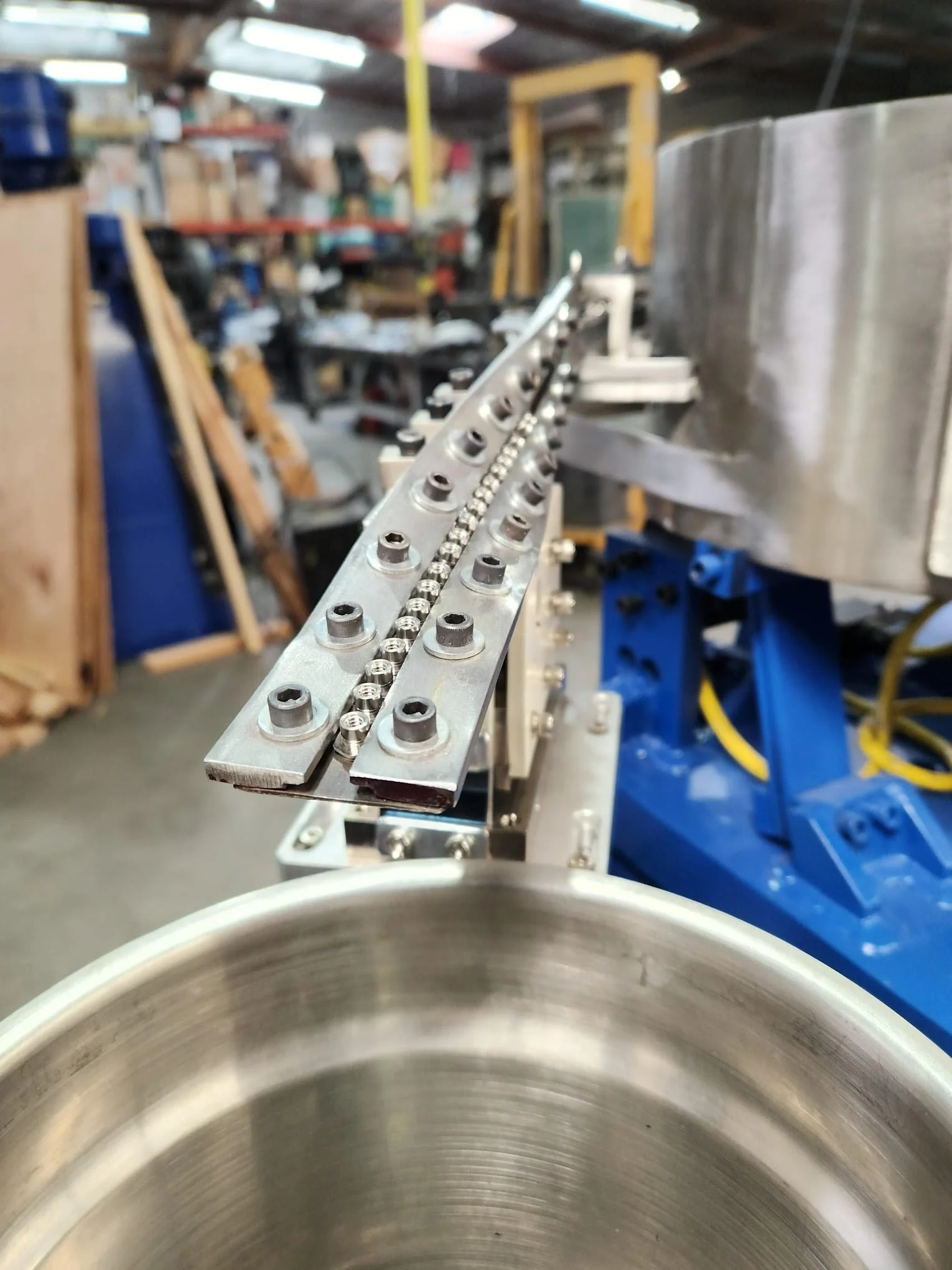

Tracks

We work with a variety of tracks such as In-lines, gravity tracks, air conveyors, merging tracks, and twist tracks

Using electric vibration, pneumatic vibration, air jets, or gravity to shuttle your parts away from the bowl to your machine operation ensures a streamlined process that maximizes efficiency.

Integrating sensors to detect when the track is full allows for the automatic shutdown of the bowl, relieving pressure to prevent forceful jamming and conserving energy in the process.

Moreover, merge tracks play a crucial role in inserting spacers between parts, particularly in grinding scenarios where precision is key. This sophisticated automation reduces downtime and enhances workflow, making your manufacturing process not only faster but also smarter.

Join us in redefining Automation Systems through innovative solutions. Each feeder bowl is a testament to our expertise and dedication to excellence. Experience the A-1 Automation difference — your business deserve nothing but the best.

Don’t see what you are looking for ?

If you don’t see what you’re looking for, don’t hesitate to contact us about custom projects tailored to meet your specific needs. Our team at A1 Automation thrives on creativity and innovation, ready to collaborate with you to develop solutions that align perfectly with your vision. Let’s transform your ideas into reality together.

Contact us.

sales@A1autofeeders.com

(714) 821 4493

79 E Grand Blvd,

Corona, CA 92879

Distributor for

The Cleveland Vibrator Company’s products include air-powered vibrators, turbine vibrators, ball vibrators, foundry vibrators, rotary electric vibrators, rotary air vibrators, electromagnetic vibrators, vibratory tables, lab tables for light-load applications, feeders and conveyors, and vibratory screeners. Their recent acquisition of HK Technologies in Salem, Ohio, allows them to offer ultrasonic fine-powder screening.

Browse through their selection of Items, Contact us, for special pricing and availability